Bulk manufactured polyoxyalkylene polymers are commonly used in the pharmaceutical industry as excipients. Light or air can catalyze oxidative degradation of these polymers via peroxidation, which may result in functionality changes and an increase in low molecular weight fragments. To minimize degradation, these polymers are commonly stabilized with antioxidants, some of which can have adverse biological effects [1]. To increase polymer stability, Maroon Biotech takes steps to minimize intermediates in order to produce oxidation-resistant polymers.

Poloxafuse® is a purified, stabilized Poloxamer 188 product available for purchase for scientific investigators and pharmaceutical manufacturers. For other high precision polymer needs, contact us at (312)432-9820 or info@maroonbiotech.com.

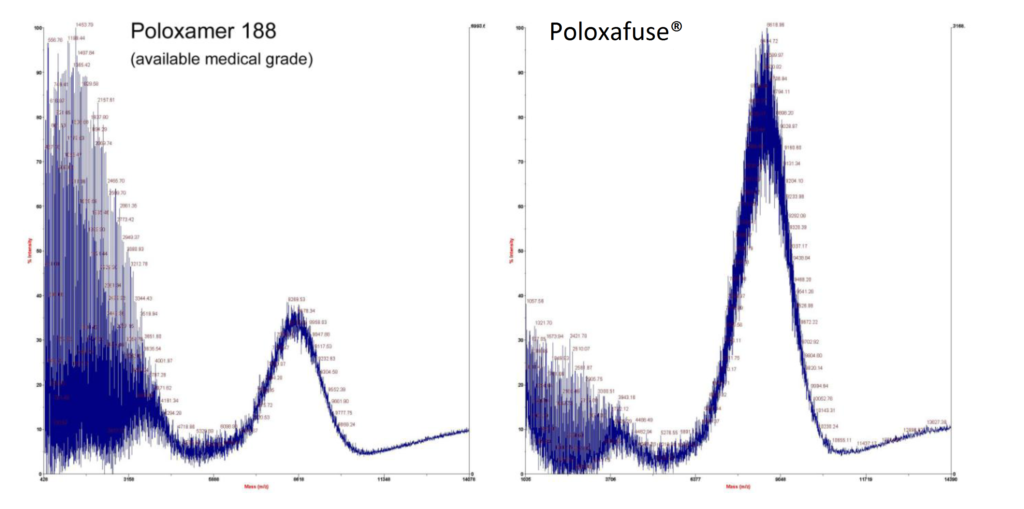

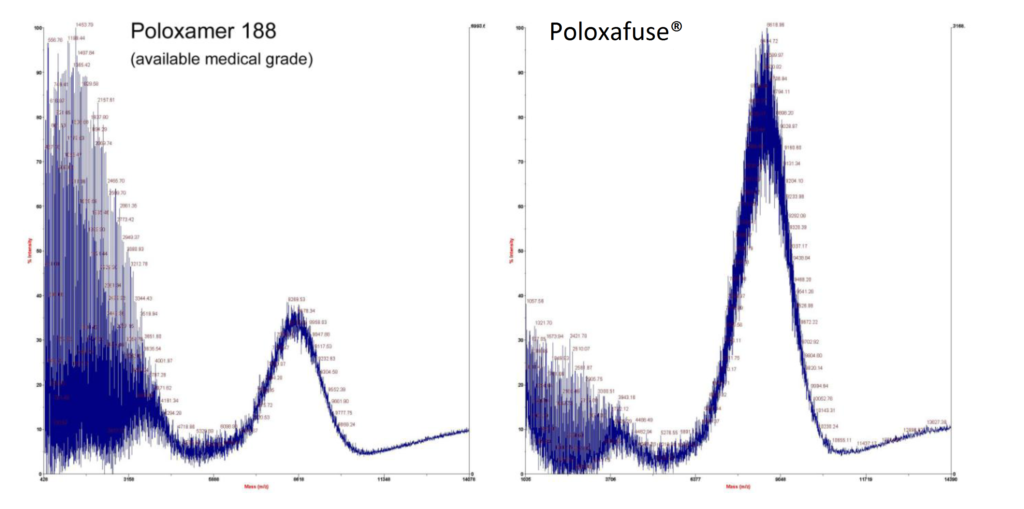

The MALDI spectra (above) demonstrate the difference in quality between Maroon P188 and medical grade bulk supply P188. Maroon Poloxafuse® contains substantially less low molecular weight fragments.

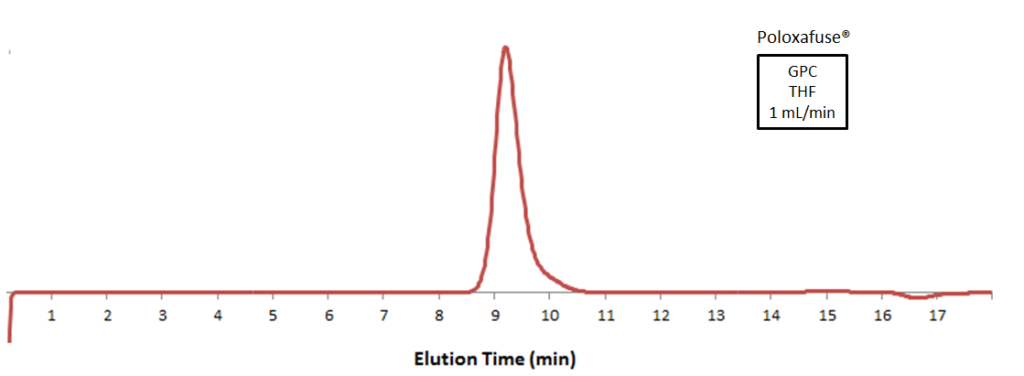

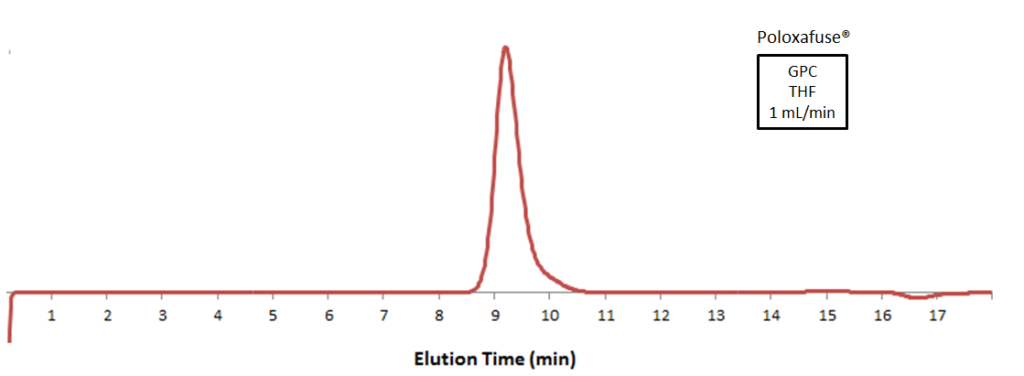

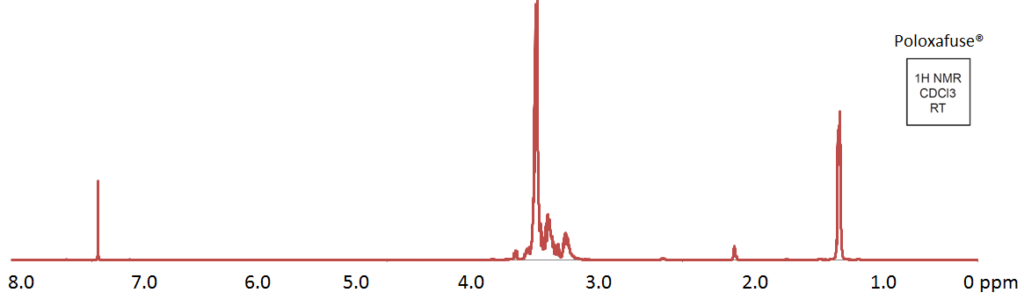

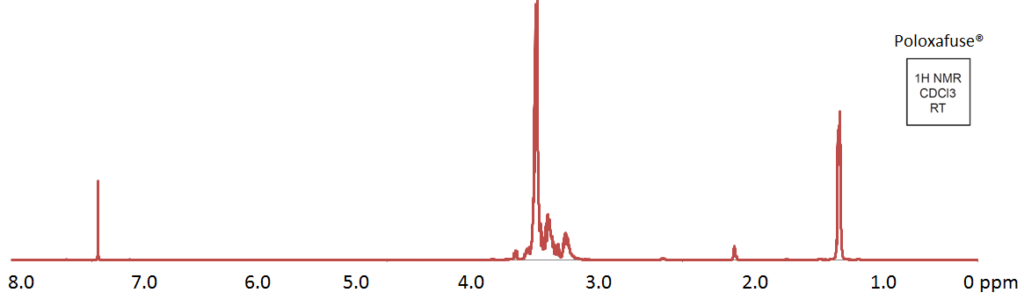

Gel permeation chromatography (GPC, above) further demonstrates the lack of polydispersity in Maroon’s P188 and nuclear magnetic resonance (NMR, below) confirms the product structure compared to literature data.

Our method is effective in producing highly purified polyethylene glycols, poloxamers, and tetronics, with the capability of further custom syntheses. To purchase research grade polymers, contact us at (312)432-9820 or info@maroonbiotech.com.

Lanigan RS and Yamarik TA. Final report on the safety assessment of BHT(1). Int. J. Toxic. 2002; 21(2): 19-94.